In today's digital age, having a strong online presence is crucial for businesses to succeed.…

Understanding Cross-Recessed Machine Screws: A Comprehensive Guide

Introduction:

Machine screws play an essential role in holding together various components and materials. One common type of machine screw is the cross recessed machine screw, which boasts a distinct design that enhances efficiency and reliability. In this article, we will delve into the world of cross-recessed machine screws, exploring what they are, how they work, and addressing frequently asked questions to help you better understand and utilize these versatile fasteners.

What are Cross-Recessed Machine Screws?

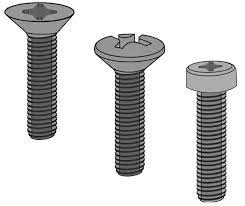

Cross-recessed machine screws, also known as Phillips head screws, are a category of fasteners designed for precise and secure fastening in a variety of applications. They feature a unique cross-shaped indentation on the screw head, which accommodates a matching screwdriver or bit. This design offers several advantages, such as reduced cam-out and increased torque transfer, making them a popular choice for many industries.

Anatomy of a Cross-Recessed Machine Screw

A cross-recessed machine screw consists of several key components:

2.1. Head: The head of the screw features the characteristic cross-shaped recess. It can be flat, pan, or round in shape, and each design has specific applications.

2.2. Thread: The threaded portion of the screw is responsible for creating a strong and secure connection when it’s screwed into a threaded hole or nut.

2.3. Shank: The unthreaded portion between the head and the thread is called the shank. Its diameter may vary, depending on the screw’s size.

2.4. Point: The point of the screw is designed to penetrate the material efficiently.

Advantages of Cross-Recessed Machine Screws

3.1. Reduced Cam-Out: The design of cross-recessed screws minimizes the risk of the screwdriver or bit slipping out during installation, reducing the likelihood of damaging the screw head.

3.2. Increased Torque Transfer: The four contact points of the cross-recessed design provide better torque transfer, allowing for more efficient and secure fastening.

3.3. Widespread Availability: Cross-recessed screws are widely available and come in various sizes and materials, making them suitable for various applications.

FAQ Section

Q1: What are the common applications for cross-recessed machine screws?

A1: Cross-recessed machine screws are used in a wide range of applications, from assembling electronics and appliances to automotive and construction projects.

Q2: What is the difference between a Phillips head screw and a cross-recessed screw?

A2: Phillips head screws are a type of cross-recessed screw, but the Phillips design is patented, while cross-recessed is a generic term. They share the same cross-shaped indentation.

Q3: Are there variations of cross-recessed machine screws?

A3: Yes, there are various head styles, such as flat, pan, and round heads. Each has its unique applications and appearances.

Q4: Can I use a regular screwdriver with cross-recessed screws?

A4: It’s best to use a screwdriver or bit designed for cross-recessed screws to ensure a secure and efficient installation.

Q5: What materials are cross-recessed machine screws typically made of?

A5: Cross-recessed screws come in various materials, including steel, stainless steel, brass, and more, depending on the application’s requirements.

Conclusion:

Cross-recessed machine screws offer a reliable and efficient way to fasten components in various applications. Their unique design, reduced cam-out, and excellent torque transfer capabilities make them a valuable addition to any toolbox. By understanding their anatomy and advantages, you can confidently choose and use these screws for your projects, ensuring secure and precise fastening.

This Post Has 0 Comments